Have you ever heard of “red mud?” It’s a rather unassuming name for a waste byproduct that’s left over during the process of turning bauxite ore into alumina.

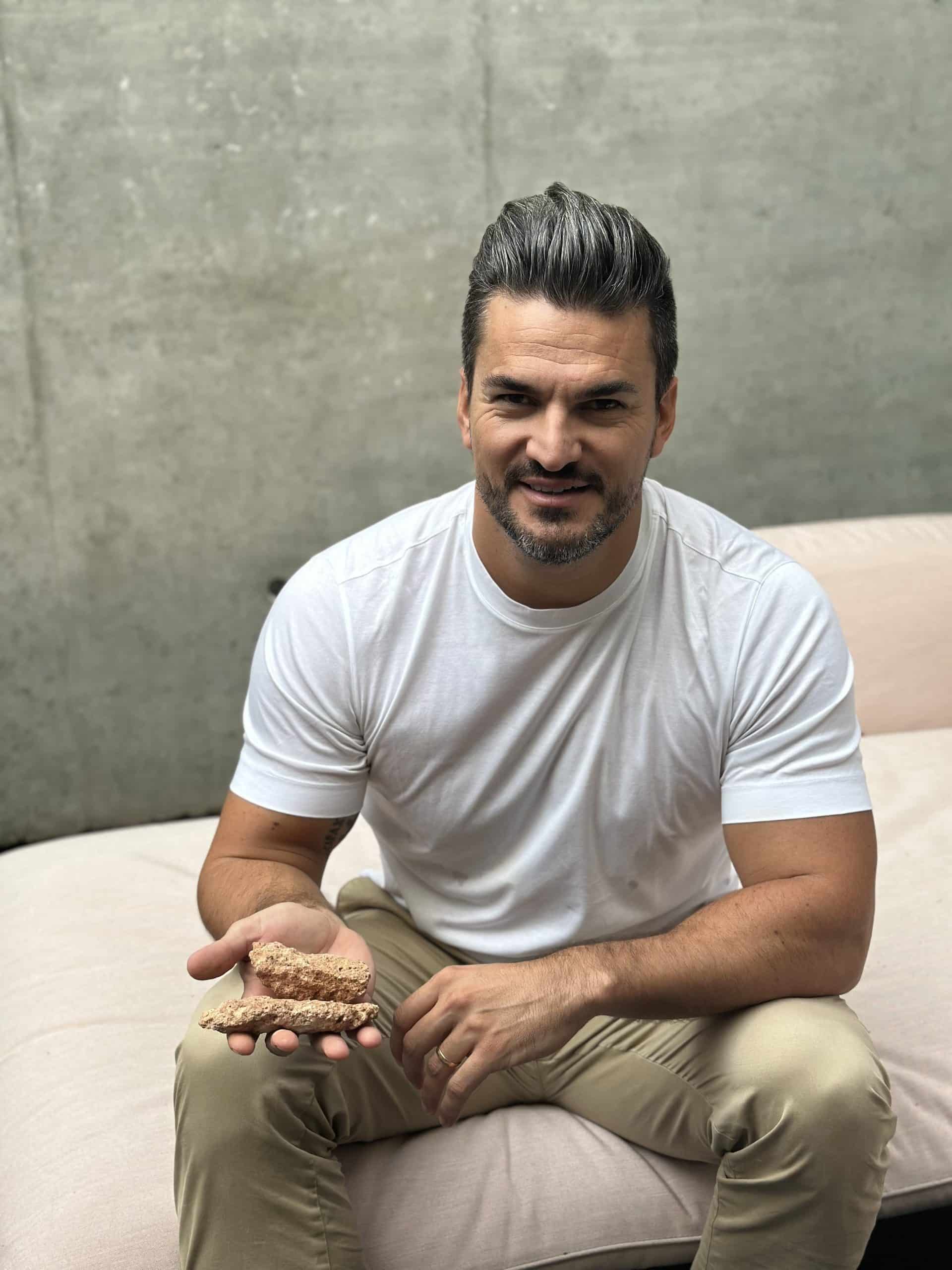

Dig a little deeper into this bauxite byproduct, and it becomes evident that it’s doing a number on our environment. A visionary thinker named Romain Girbal partnered with Yves Occello as he introduced a game-changing solution called IB2 (Improved Bauxite, Improved Bayer). Turns out, this holds the potential to address and mitigate the red mud fiasco we’re facing.

IB2 steps in by transforming low-grade bauxite into high-quality ores, improving operations and slashing the production of toxic red mud by 70%. This revolutionary process offers relief to both the planet and refineries grappling with red mud storage issues. The traditional method of converting low-grade bauxite into alumina involves high energy consumption and significant CO2 emissions. IB2 technology, however, is making remarkable strides in reducing these harmful emissions.

Despite its transformative potential, IB2 isn’t a quick fix. Implementing changes in industry is akin to steering a large ship—it requires time and effort. Nevertheless, IB2 provides a promising path forward, enhancing the cleanliness and environmental friendliness of bauxite refinement.

Think of Romain Girbal’s vision as a flashlight in a dark tunnel. He’s not just trying to fix a problem; he’s trying to light the way to a better, cleaner future. Sure, there might be bumps along the road, but the idea of having less red mud waste and a healthier atmosphere is worth the effort.

To wrap it up, “red mud” might not be a term that resonates, but it represents a critical problem that needs solving. Thanks to IB2, there’s hope on the horizon. Romain Girbal‘s visionary creation holds the promise of less red mud, fewer CO2 emissions, and a bauxite refinement process that embraces a more Earth-friendly approach.

- “As chicaadmin at The Chicago Weekly, I curate trending national and international news stories with a focus on social justice and cultural impact. My passion for journalism and commitment to independent media are fueled by my Chicago roots and belief in the power of storytelling to connect communities. Follow me on Twitter for insightful commentary and news updates!”